AEG ID - Your partner for customized transponders & readers

Published:

RFID WIOT SEARCH OCTOBER 2022

Customers benefit from RFID competence for Transponders and Readers!

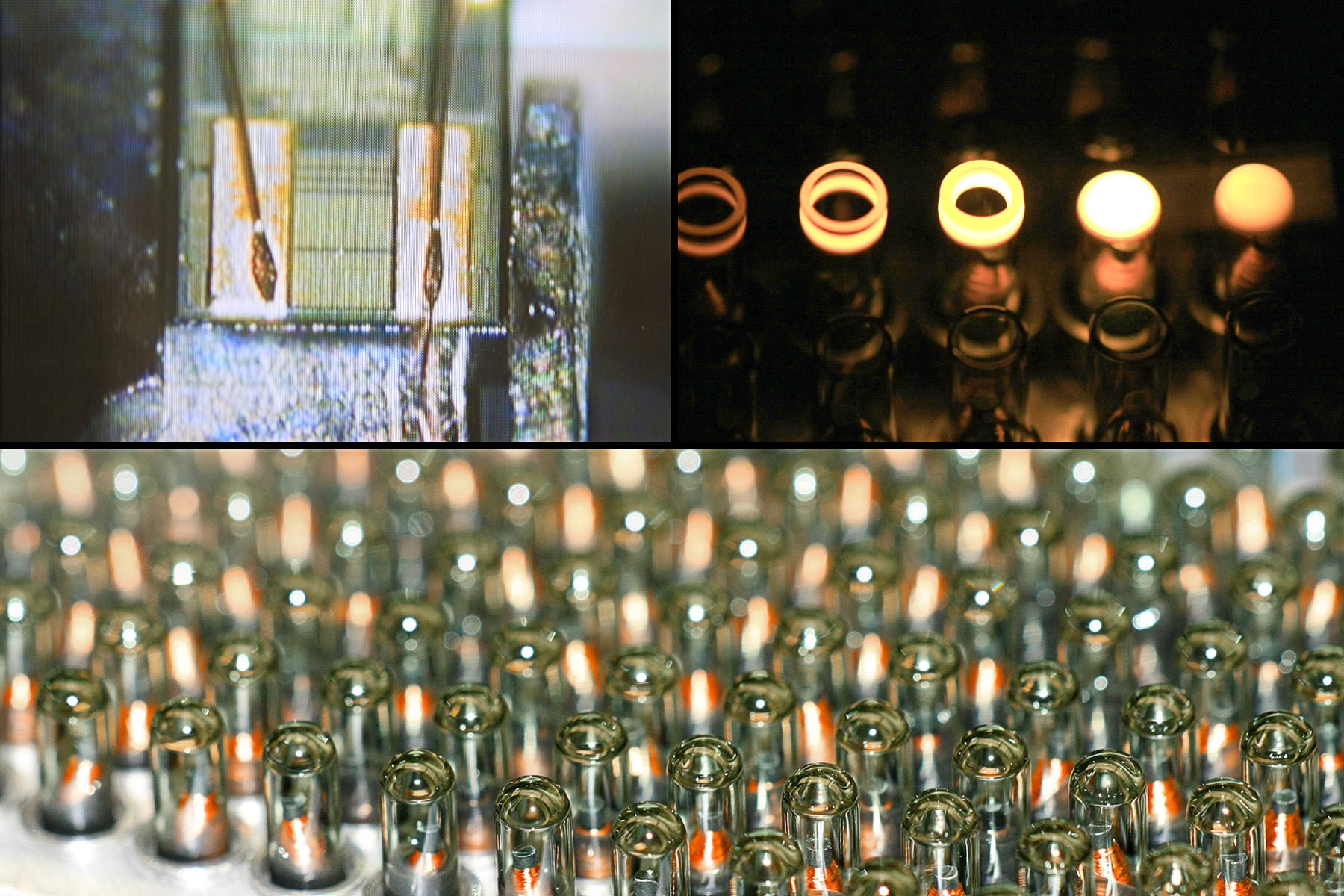

AEG ID has been developing and producing RFID components since 1989. The know-how ranges from chips to transponders to readers and antennas. Production takes place at the company's headquarters in Ulm, Germany, and in Vrchlabi in the Czech Republic. Thanks to many years of experience and RFID expertise, the company is able to adapt products precisely to customer requirements during product development. The result: individual functionalities, designs and applications for RFID are realized.

Core competence for RFID Transponders and Readers

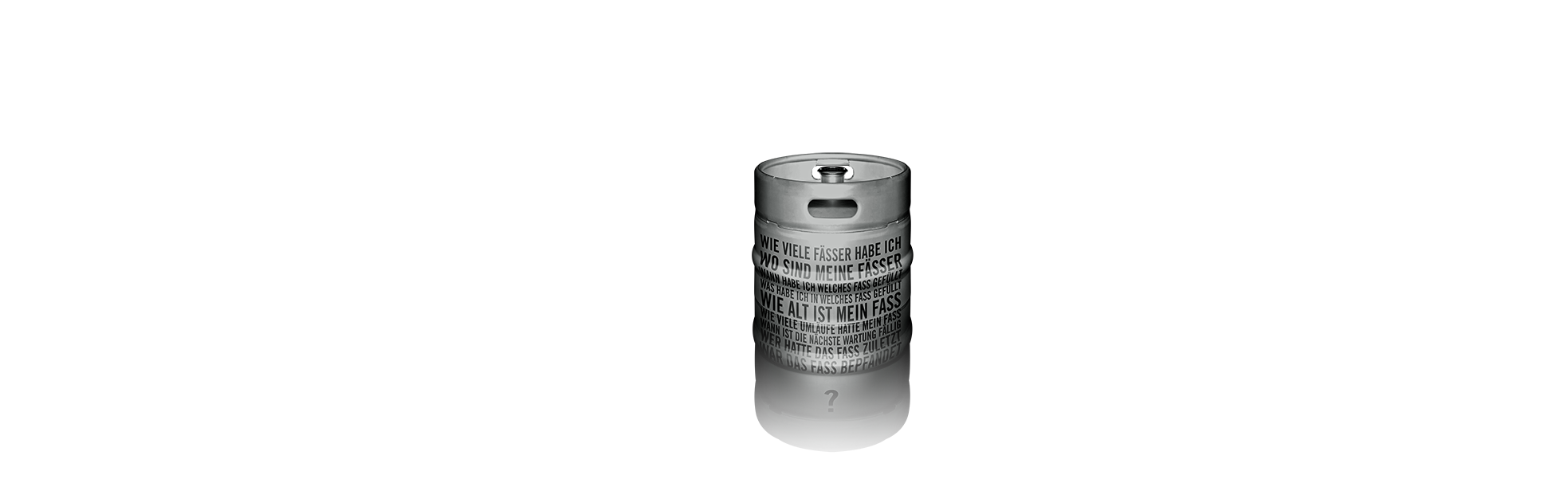

With the production capacities at the two company locations, smallest quantities up to international bulk orders are handled. The RFID products are used for animal identification, industry, logistics, access control, time recording, maintenance, service and inventory management as well as container management. AEG ID products are also used in security-related and government sectors.

"AEG ID has a wide range of customers and segments. The company offers a cross-application portfolio without specialization in any one area," explains Simon Arch, Director of Marketing and Sales, AEG ID. "There are significantly more requests from the market for completely new RFID applications."

Customization increasingly in demand

Product development in the RFID industry is increasingly following a trend: customers are already integrating RFID in the development phase. AEG ID accompanies product development and adapts products to customer requirements.

"The market requires significantly more tailor-made RFID solutions – also often in combination with transponders and readers", says Simon Arch. "It's not enough to just offer a reader. Manufacturers must be able to respond to individual requirements. The design or reading range is customized."

Customers benefit from AEG ID expertise in Transponder and Reader development

AEG ID manufactures both RFID transponders and readers. This offers customers decisive advantages for product development, emphasizes Simon Arch:

"The development of transponders and readers from a single source strengthens process control and reliability. The RFID components are precisely matched to each other. Furthermore, customers have a dedicated contact person in case of questions or special requirements. The ongoing technological optimizations and adaptations are therefore possible to be completed faster and easier. AEG ID is the dedicated contact already in product development as well as for RFID transponder integration in

accordance with our motto 'we make ID easy'."